Articles

Your cool room construction has been completed, rooms are down to temperature and you’re ready to stock up with your product.

But before you do anything, there’s one important thing ASKIN offers to protect your business. A thermal image scan.

What is a thermal image scan?

Thermal imaging or thermography is when specialised photographic equipment is used in cool rooms, freezers and temperature-controlled facilities to identify variances in temperature through vapour leakage or thermal transfer. ASKIN’s scan will pinpoint the exact location of a possible thermal leak between panel and connection points. The thermal images are accurate to one-tenth of a degree. It’s an effective method of protecting your business’s assets and gives you peace of mind.

What are the benefits for the end user?

A vapour, air-leak or thermal transfer will cause temperature loss, limiting the shelf life of product and an increase in energy cost. Safety is also a factor to be aware of. Air leakage and thermal transfer result in condensation and ice. This is not a good combination in traffic areas, causing a slip and fall hazard for your employees and possible control loss of lifting equipment. A thermal scan will help prevent these issues, ensuring your facility is running as it should be, safely and efficiently.

Benefits for the installer

An ASKIN provided thermal scan prior to the handover of your rooms, gives the opportunity to identify a failing in the installation or panel system before the rooms are filled with stock. The thermal scan itself can be carried out whilst the room is stocked however, the risk comes with the repair being required around operating hours and site staff, not to mention the risk of litigation should a site employee take a fall as a result of ice or condensation.

The Good

This freezer at -20degC has walls and ceiling backing on spaces with ambient temperatures +18deg C. This 38degC temperature differential will highlight quite dramatically areas of low insulation. However, the panel to panel joints are clearly well sealed and barely discernible. Mushroom fastenings show clearly which is to be expected with a metal fastening. Due to the larger external surface area of the wall to ceiling joints, it’s normal to have slightly warmer temperatures in the corners.

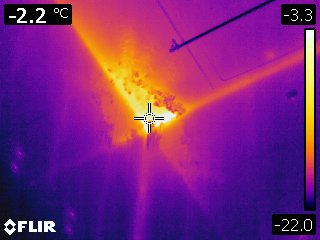

The Bad

A leak in the vapour barrier in the corner of a cool store at the ceiling wall intersection. This is exacerbated by the CCTV installation but is bad enough to have ice build up shown by the granular looking material around the hotspot.

When is it best to use thermal imaging

ASKIN recommends a thermal image scan as part of their installation service. It’s best performed at the completion of a cold room or freezer construction, in conjunction with the refrigeration being commissioned. This will detect vapour leakage or thermal transfer in the insulated panel system. Thermal imaging is a non-intrusive preventative maintenance activity that can also be done when your business is in full operation.

Now you can see the benefits of thermal imaging, how it can help protect your employees from injury, your business from increased energy and save you money on maintenance costs.

ASKIN offers thermal scanning as part of their installation or supply only service to give you peace of mind that your facility is 100% airtight, energy efficient with superior insulation. Why not give us a call to see how we can help you with your next temperature controlled facility.

As a professional cold room installer, we understand your building and its requirements and know what we are looking for when conducting a scan.